Green transition at Norske Skog Golbey

15/09/2022

Despite the heat waves, work continues at Golbey. During the summer, Norske Skog Golbey has begun its transformation. Four different parts of the mill are already impacted by the conversion.

Some of these works are not only part of the conversion but more broadly key drivers of the energy transition the mill started years ago.

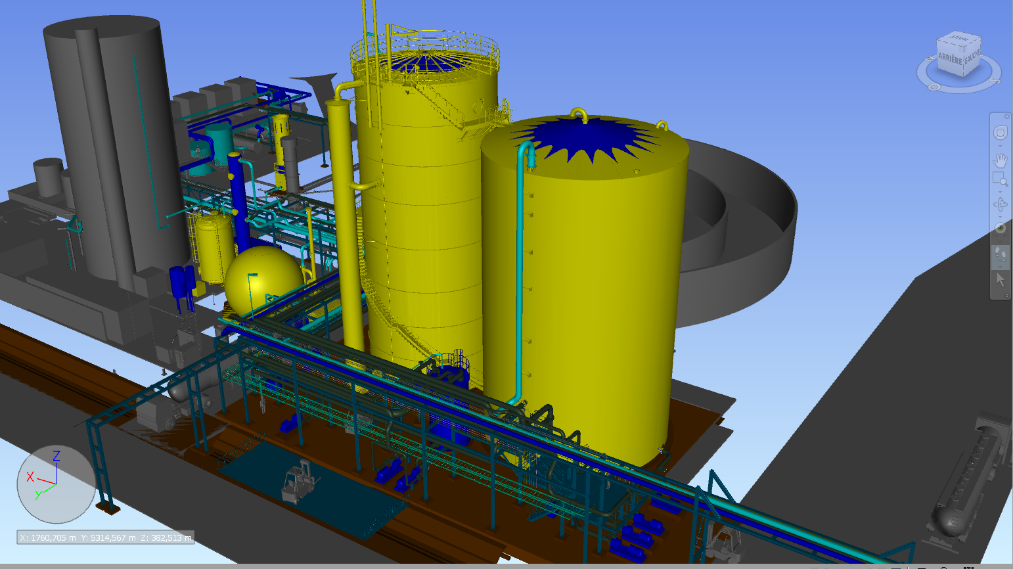

- The construction of the second biogas production line: this new unit will allow Norske Skog Golbey to further reduce its dependence on fossil fuels. Thanks to these new facilities, the biogas production in the mill will more than double from 2023 on. This biogas produced from the effluents of the paper production will either be sold and injected into the gas network, or burnt on site to replace part of the fossil natural gas that is used as additional fuel on our boilers when needed.

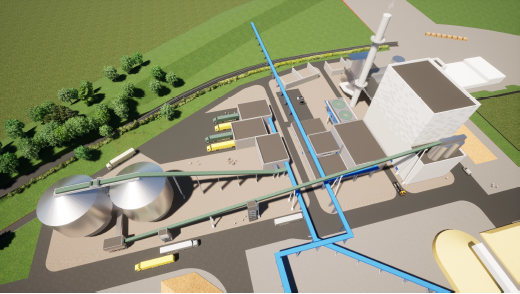

- The construction of the new biomass boiler has also begun. Coupled with a steam turbine, it will enable the production of renewable energy thanks to the use of non-fossil fuels: end-of-life wood and waste from cardboard to be recycled. This project, which is part of the 5th call for tenders from the French Energy Regulation Commission, is being carried out by a project company (GVE) composed of Pearl Infrastructure Capital, Veolia Industries Global Solutions and Norske Skog Golbey. With this new boiler, added to the existing ones, Norske Skog Golbey will have the steam required by the mill after the conversion for both the newsprint and containerboard production.

“Green Valley Energie is much more than a major industrial and economic project. It is a sustainable project, which will allow hundreds of tons of biomass waste to be converted into electrical and thermal energy with a minor impact on its environment. This is the essence of this amazing project which will have a positive impact on both Norske Skog Golbey and the whole region !", said Alexandre de Cuniac, CEO of GVE.

Decreasing dependence on fossil fuels and reduce our carbon footprint

Martine Bortolotti, Norske Skog Golbey Head of Sustainable Development and Transversal Projects

“The current projects go far beyond a simple machine conversion. They are fully in line with our CSR approach and contribute to achieving our environmental objectives.

For years, we have been working to optimise our energy consumption and reduce our dependence on fossil fuels. For example, between 2006 and 2022, we have reduced our natural gas consumption by 66%, largely by replacing this fuel with end-of-life wood. Our steam is now produced with more than 80% non-fossil fuels. The current crisis makes it even more important to act quickly.

As part of the evolution of our activities, we are seizing new opportunities for improvement by further reducing our energy consumption (approximately -30% electricity and -50% fossil natural gas) and our dependence to fossil fuels thanks to the new boiler, the associated steam turbine and the second biogas line. By increasing the production of renewable energy, these new facilities will not only meet our growing needs generated by the increase in our paper production capacity, but will also contribute to improving our environmental footprint in order to reach our objective of reducing our C02 emissions by 55% between 2015 and 2030.

More than ever, Norske Skog Golbey wants to be a sustainable supplier of paper in the years to come”